Präzision nach Ihren Daten

Seit mehr als 25 Jahren produzieren und konstruieren wir individuelle Werkzeuge, die durch Qualität überzeugen

Wir suchen Unterstützung für unser Team!

JoRe Werkzeugbau GmbH.

Wir bauen hochwertige Stanzwerkzeuge, Umformwerkzeuge, Folgewerkzeuge, Transferwerkzeuge, Prototypenwerkzeuge und Einlegewerkzeuge vor allem für Automobil-Hersteller und Zulieferer.

Kunden wie BMW, Mercedes Benz, Volkswagen, Porsche, Linde & Wiemann, Gestamp, Benteler und viele andere schätzen seit mehr als 25 Jahren die Präzision und die Durchlaufzeiten von JoRe-Werkzeugen. Das JoRe-Team Standort Verl sorgt für eine hohe Kundenzufriedenheit sowie termingerechte Produktionen.

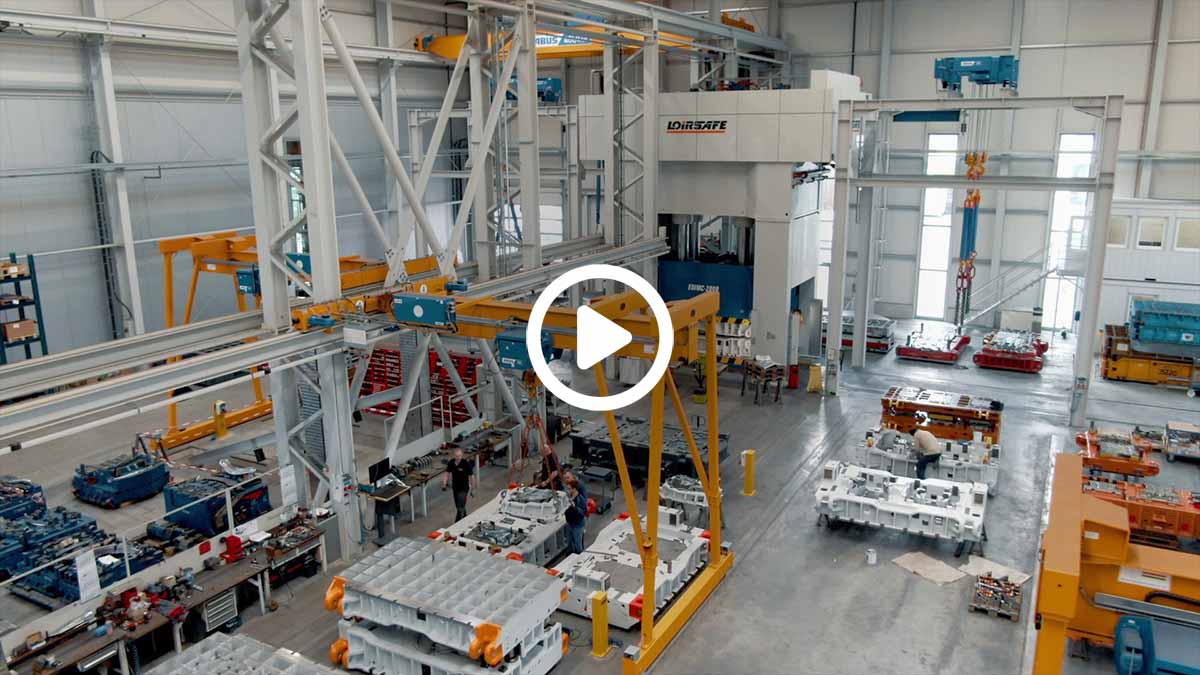

Unser global ausgerichtetes Unternehmen punktet mit einem modernen Maschinenpark und unseren ca. 85 Mitarbeiter/Innen (inkl. ISPA engineering), die ihr Handwerk verstehen:

Unsere Werkzeugmechaniker und Zerspanungsmechaniker arbeiten mit modernen Maschinen und in Handarbeit. Unsere Fertigung ist dank der CAD/CAM-Software Tebis papierlos. So entstehen Präzisionswerkzeuge mit bis zu 40 Tonnen Gewicht und ein Spektrum von über 500 Bauteilprojekten.

Die Lohnfertigung ist ebenfalls ein wichtiges Geschäftsfeld. Neben der Fertigung kompletter Werkzeuge stellen wir seit langem erfolgreich unsere Zerspanungskompetenzen zur Verfügung. Hierzu greifen wir auf unseren modernen und vernetzten Maschinenpark zurück.

Auf die Dienste der Konstruktionsingenieure in unserem Konstruktionsbüro ISPA Engineering können wir jederzeit zurückgreifen. Im intensiven Austausch entwickeln die Ingenieure aus Konstruktion, Fertigung und auf Kundenseite flexible und zeitnahe Problemlösungen. Zur direkten Kommunikation zwischen Fertigung und Konstruktion nutzen wir das Tebis-System zur papierlosen Fertigung.

Aktuelle News

JoRe Werkzeugbau ist jetzt TISAX-zertifiziert

Datenschutz ist heutzutage ein zentrales Thema, das Unternehmen in allen Branchen betrifft. Insbesondere für Werkzeugbau-Unternehmen ist der Schutz sensibler Daten von größter Bedeutung. Wir freuen uns daher, dass wir kürzlich die TISAX-Zertifizierung erhalten haben....

25 Jahre JoRe Werkzeugbau

Das Unternehmen JoRe Werkzeugbau feiert in diesem Jahr sein 25 jähriges Bestehen. Wir danken allen Mitarbeitern, Kunden und Lieferanten für die gute Zusammenarbeit in den letzten Jahren und freuen uns auf die Zukunft!

Eine 2000 Tonnen Presse für JoRe Werkzeugbau

Seit Anfang des Jahres 2018 können wir auf unsere eigene 2000t Loire Safe Presse zurückgreifen.Wir sind stolz eine von wenigen Loire Safe Pressen in unserem Maschinenpark zu haben, bei den alle wichtigen Komponenten aus Deutschland stammen.Mit einer Tischgröße von...

Ausgezeichnete Qualität.

Das 1995 von Frank Johannhörster und Michael Reker gegründete Unternehmen JoRe Werkzeugbau GmbH steht für Qualität und Zuverlässigkeit.

Dies bestätigt das Zertifikat des DQS für das Managementsystem nach DIN EN ISO 9001:2015.

Seit 2023 sind wir TISAX-zertifiziert, um sicherzustellen, dass vertrauliche Kundendaten besser geschützt sind.

| Mai 1995 | Frank Johannhörster und Michael Reker gründen die JoRe Werkzeugbau GmbH nmit Firmensitz in Rheda-Wiedenbrück. Hallen- und Produktionsfläche: 600 m² |

| September 1996 | Eine eigene Konstruktionsabteilung entsteht. |

| November 1997 | Kauf eines Firmengeländes in Verl mit 3.000 m² |

| Dezember 1998 | Aufbau einer Abteilung für Qualitätssicherung |

| September 1999 | Baubeginn der neuen Produktionsstätte in Verl mit 1.200 m² |

| Oktober 1999 | Zertifizierung nach DIN ISO 9001 |

| April 2000 | Unternehmensumzug nach Verl |

| August 2001 | Erweiterung des Verler Neubaus auf 1.600 m² |

| Januar 2002 | Gründung der ISPA GbR: die bis dato interne Konstruktionsabteilung wird eigenständig |

| März 2002 | Kauf eines weiteren Grundstückes in Verl mit 2.200 m² |

| November 2003 | Integration von eigenen Ziehsimulationsplätzen (Software Autoform) |

| 2003–2007 | Konsolidierungsphase |

| Januar 2007 | Erweiterung der Bürofläche um 200 m² sowie der Hallenfläche um 350 m² |

| April 2008 | Die Benteler Automotiv AG zeichnet die JoRe Werkzeugbau GmbH als n„Best Supplier of the Year 2007 for Toolings“ aus |

| August 2008 | Kauf eines weiteren Grundstückes in Verl mit 2.050 m² und einer Halle mit 400 m²nDamit wächst die Grundstücksfläche in der Chromstraße auf über 7.000 m² |

| März 2009 | Die ISPA Engineering stellt ihre Konstruktionssoftware von AutoCAD auf Catia V5 um |

| Juli 2009 | Inbetriebnahme des CNC/CAM-Hochleistungsfräszentrums Zayer „Tebas“ (5.000 × 3.000 × 1.100 mm) |

| Mai 2010 | Einführung der papierlosen Fertigung (TEBIS-Terminals in der Fertigung)nInbetriebnahme des CNC/CAM-Hochleistungsfräszentrums Zayer „Memphis“ (3.000 × 2.050 × 1.100 mm) |

| August 2010 | Einführung eines ERP-Systems. Eine Eigenentwicklung und damit direkt auch die Anforderungen des Werkzeugbaus zugeschnitten |

| 2011 bis 2013 | Konsolidierungsphase |

| 2013 | Anschaffung zweier 5-Achs Bearbeitungszentren:n- Grob G550T (900mm x 800mm x 1.000mm)n- Haas UMC 750 (630mm x 500mm x 500mm) |

| Januar 2014 | Erweiterung von Produktions- und Bürofläche durch Erwerb des Nachbargeländes |

| 2015 und 2016 | Konsolidierungsphase |

| 2017 | Planung neue Werkhalle mit Presse |

| 2018 | Bau der Werkhalle | Kauf einer 2000to Presse |

| 2019 | Inbetriebnahme der neuen 2000qm Werkhalle und der 2000to Presse |